Brochure

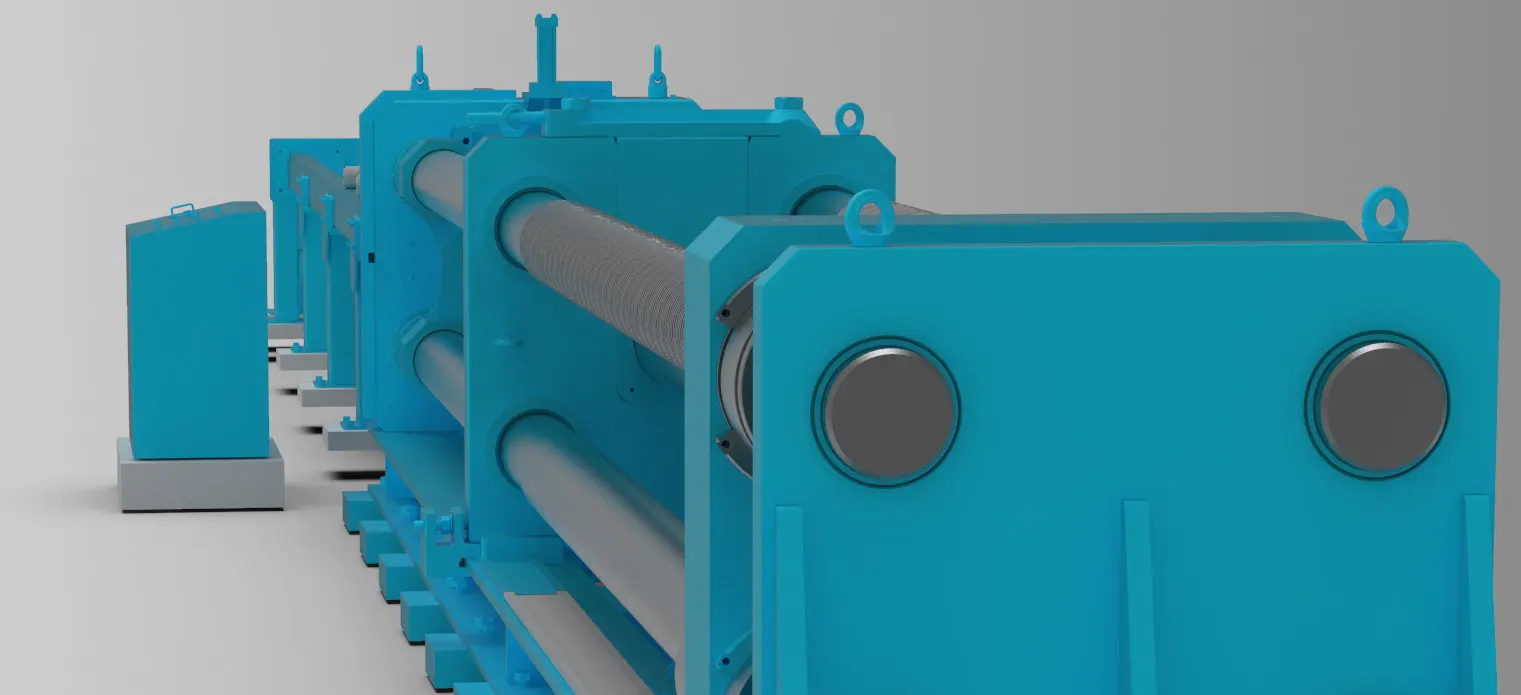

Strategic Technology in Large-Caliber Barrel Manufacturing

By applying controlled high pressure to the inner surface of gun and tank barrels, this process induces plastic deformation, significantly increasing their crack resistance and service life.

Highlights

-

Strategic Manufacturing Technology

This critical technology, possessed by only a limited number of countries worldwide, enhances the resistance of barrels to higher internal pressures. By significantly increasing fatigue life and strength, it makes them suitable for long-term and intensive use.

-

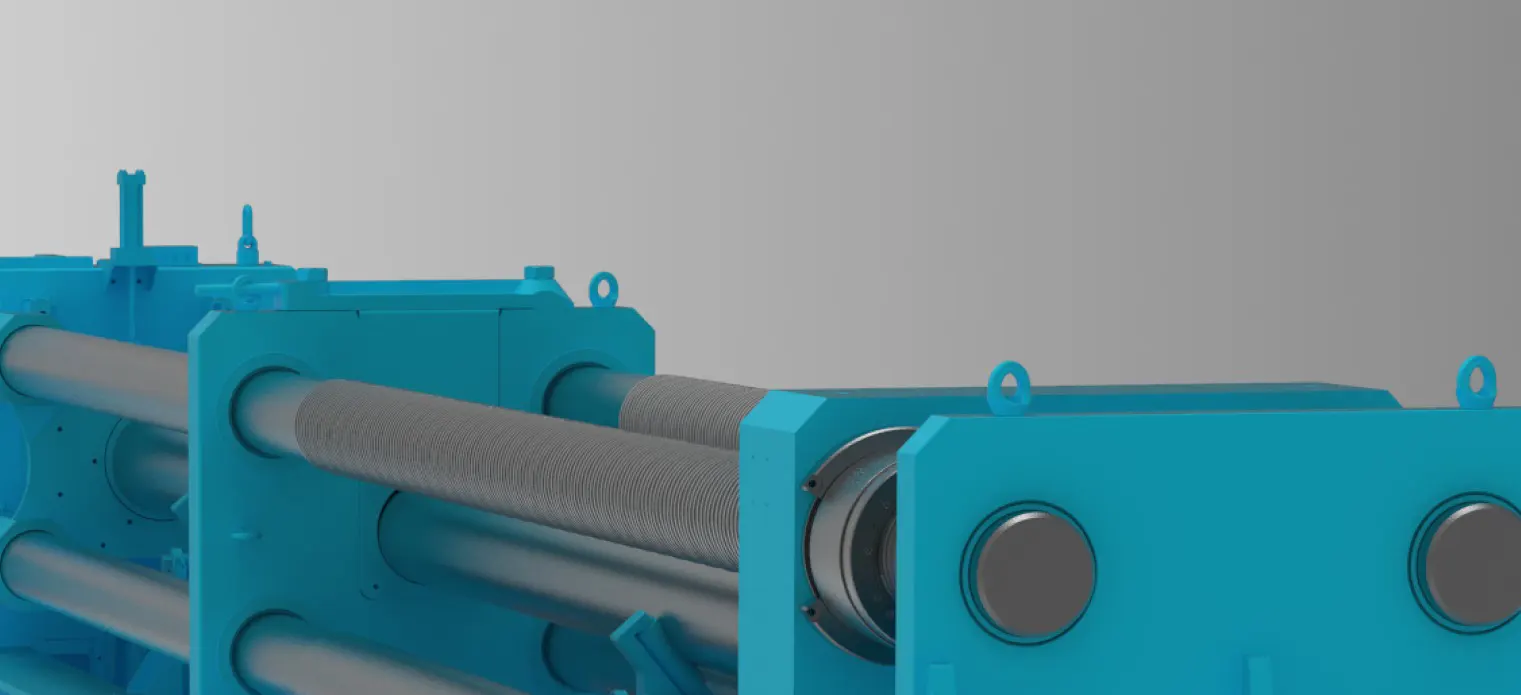

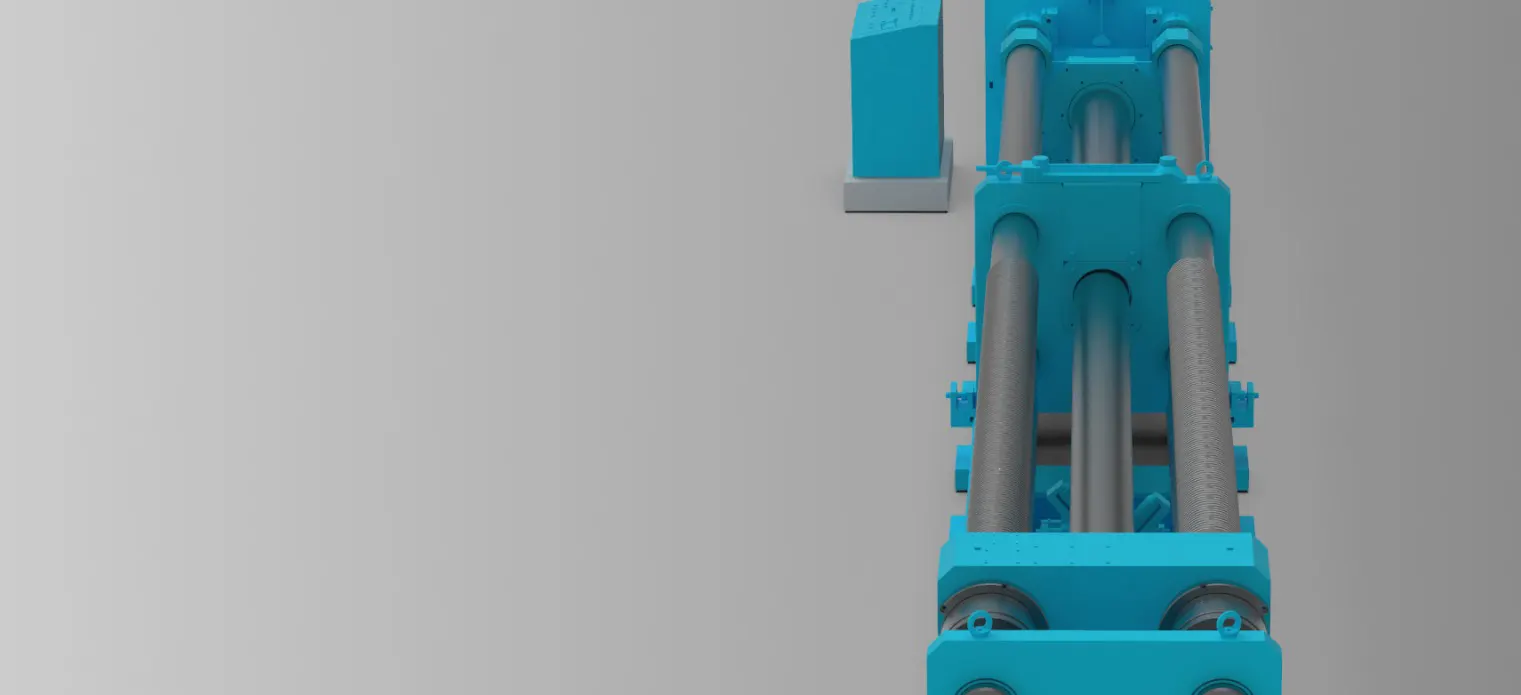

High Pressure and Precision Control

Capable of applying pressure up to 14,000 bar to barrels ranging from 76 to 155 mm in diameter. Performs regional autofrettage using a precision control unit that ensures metallurgical compatibility through barrel-specific pressure profiles.

-

Full Automation and Safety

The PLC and HMI-controlled process system minimizes human error. With over 20 sensors monitoring pressure, position, and temperature, automated fault detection and maximum safety systems remain active at all times.

TECHNICAL FEATURES | DESCRIPTION |

|---|---|

Precision Control Unit | Ability to apply pressure profiles based on requirements |

Full Automation | PLC and HMI controlled process system |

Safety Systems | Automatic fault detection and maximum safety systems |

Multi-Point Measurement | Monitoring of pressure, position, and temperature with over 20 sensors |

Regional Processing Capability | Targeted application to specific areas only |

Logging and Reporting | Data recording and analysis system for each operation |

Remote Access | Operational monitoring and remote intervention capability |

Barrel Diameter Compatibility | 76 mm - 155 mm |

Barrel Length | 1.000 mm - 11.000 mm |

Operating Maximum Pressure | 12.000 bar |

System Maximum Pressure | 14.000 bar |

See More

Our Core Advantages

Önder Defense’s Approach

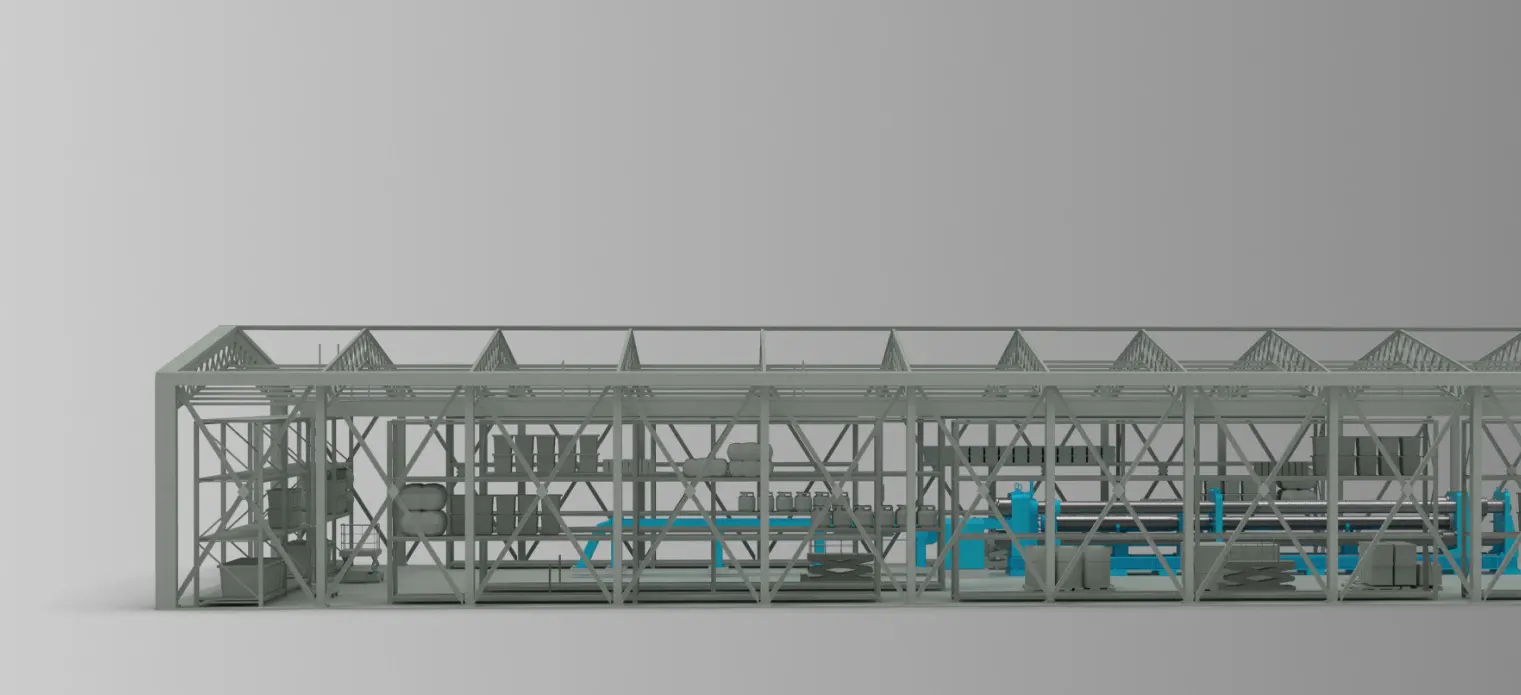

Önder Savunma adopts the strategic priority of nationalizing critical technologies in the defense industry and eliminating foreign dependency. We offer advanced solutions ranging from hydraulic autofrettage technology—owned by only a few companies worldwide—to modular propellant system production equipment. With the special manufacturing technologies developed for MKE Inc. facilities, we contribute to the technological autonomy of our defense industry by increasing both capacity and quality consistency.

Precision Fire, Secure Operation

Modern defense industry requires high-performance barrel manufacturing and precision ammunition logistics. The ability of artillery and tank barrels to withstand high pressures and maintain performance during intense firing rates is critical. Hydraulic autofrettage process increases barrel pressure resistance while doubling its service life. Our specially designed crates for the safe transport and storage of anti-tank ammunition maximize operational efficiency.

Smart Systems, Strong Defense

Advanced automation systems and modern electrical instrumentation ensure precise process control in production workflows. Our modular propellant system production equipment increases capacity by 60% while reducing waste by 25%. Consistent manufacturing with new-generation equipment and molds, efficient material flow through advanced piping systems, and minimized operator errors thanks to advanced automation provide both workplace safety and product quality consistency.

Operational Superiority

-

Technological Depth

Optimal material behavior achieved by intervention only in necessary areas

-

Domestic Production

Complete independence from foreign sources through fully local engineering and manufacturing infrastructure

-

Defense Industry Compatible

Perfect compatibility with tank, howitzer, and artillery systems through specialized design

-

Performance Increase

Approximately double service life with up to 40% increase in durability guarantee

-

Flexible Compatibility

Modular structure compatible with barrels of various lengths and diameters

-

Applications

Selective strength enhancement in large-caliber tank/howitzer barrels and critical areas

Controlled Plastic Deformation on the Inner Surface of the Barrel

Approximately Twice the Service Life with Up to 40% Increase

Targeted Processing Applied Only to Critical Areas

Increasing Crack Resistance by Inducing Residual Stresses

“Önder Savunma's Hydraulic Autofrettage Bench developed for MKE is an innovative step, especially in the production of large-caliber weapon systems. Thanks to its regional autofrettage capability, it targets only necessary areas on the material, extending barrel life along with pressure resistance.”