Önder Defense’s Approach

Önder Savunma adopts the strategic priority of nationalizing critical technologies in the defense industry and eliminating foreign dependency. We offer advanced solutions ranging from hydraulic autofrettage technology—owned by only a few companies worldwide—to modular propellant system production equipment. With the special manufacturing technologies developed for MKE Inc. facilities, we contribute to the technological autonomy of our defense industry by increasing both capacity and quality consistency.

Precision Fire, Secure Operation

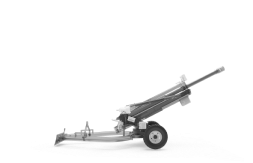

Modern defense industry requires high-performance barrel manufacturing and precision ammunition logistics. The ability of artillery and tank barrels to withstand high pressures and maintain performance during intense firing rates is critical. Hydraulic autofrettage process increases barrel pressure resistance while doubling its service life. Our specially designed crates for the safe transport and storage of anti-tank ammunition maximize operational efficiency.

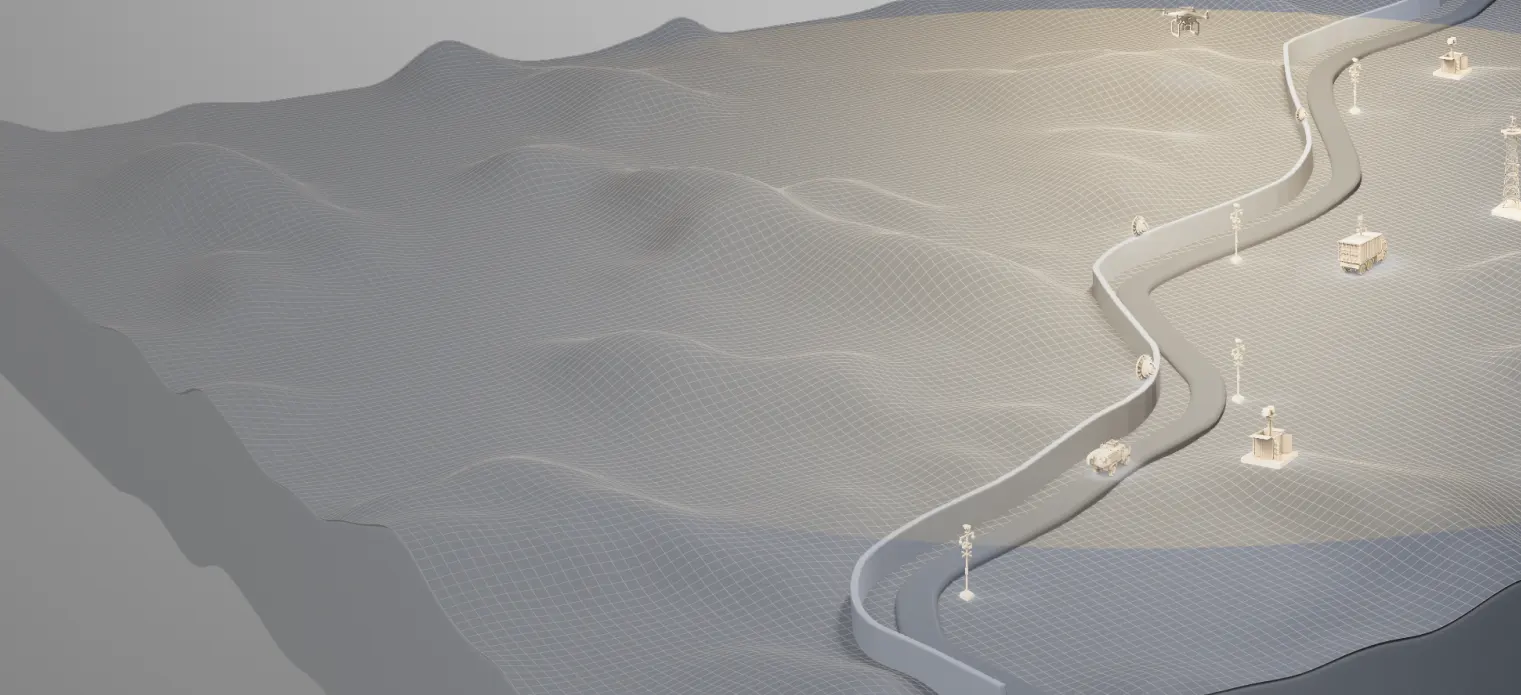

Smart Systems, Strong Defense

Advanced automation systems and modern electrical instrumentation ensure precise process control in production workflows. Our modular propellant system production equipment increases capacity by 60% while reducing waste by 25%. Consistent manufacturing with new-generation equipment and molds, efficient material flow through advanced piping systems, and minimized operator errors thanks to advanced automation provide both workplace safety and product quality consistency.

Our Categorical Products and Solutions

-

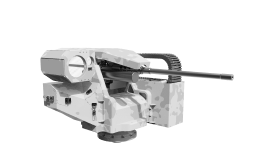

Hydraulic Auto Braking Bench

Logistics Support

Hydraulic Auto Braking Bench

By applying controlled high pressure to the inner surface of gun and tank barrels, this process induces plastic deformation, significantly increasing their crack resistance and service life.

-

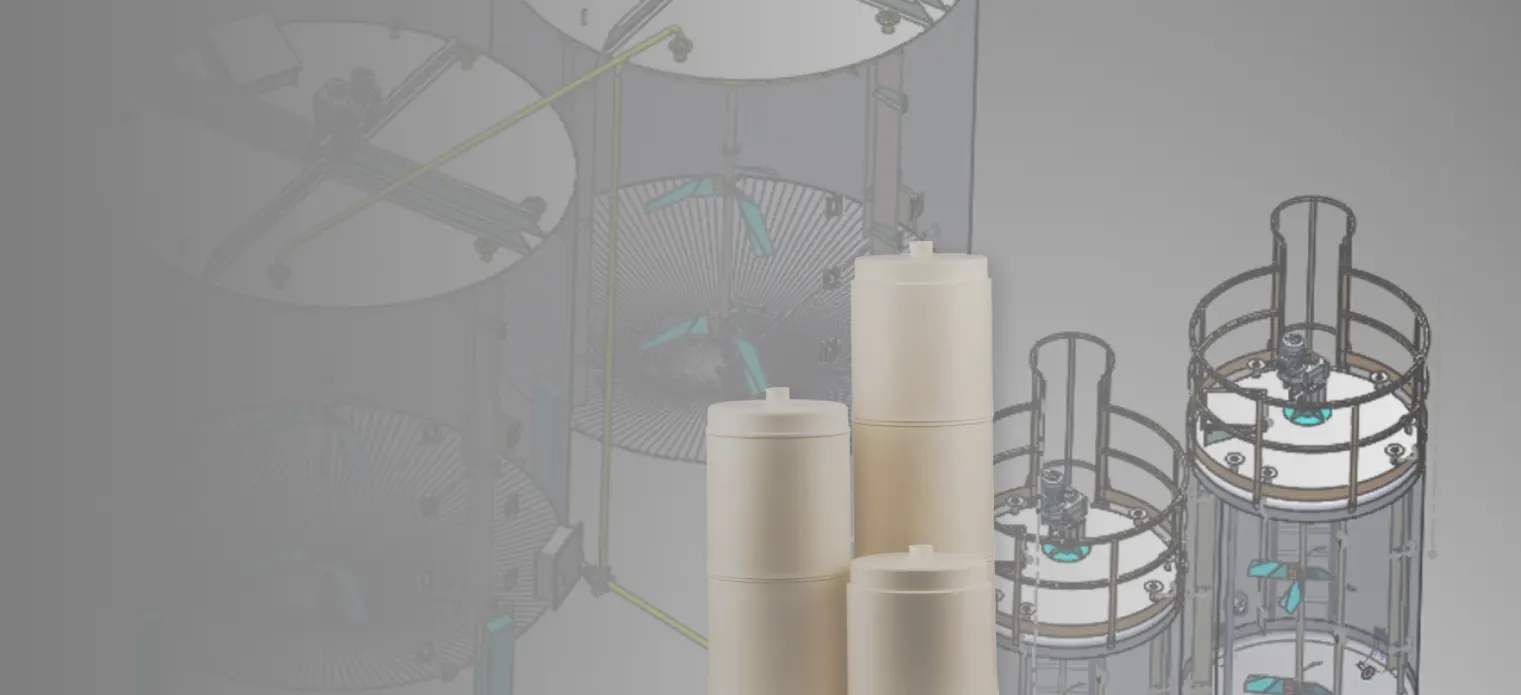

155mm Modular Charge System

(MCS) Combustible Case ProductionLogistics Support

155mm Modular Charge System

(MCS) Combustible Case ProductionDiscover the innovative solutions offered by Önder Defence Inc. in the field of testing and certification services. Superior engineering products in the Products and Technology category.

Products

Barrelled Weapons and Armed Turrets

Radars and Sensors

Command-Control-Information (C2I) Systems

Land Vehicle Subsystems

Logistics Support